Capabilities

We specialize in small, intricate parts. All of the parts we build are smaller than 1” in diameter. With our Tsugami Swiss-style screw machines we consistently hold the tightest tolerances.Tight Tolerances

Here are some examples of tight tolerance work that we built on our machines.This part has a tolerance of +/-.0002” on the ID hole and also required off-center face milling to produce the spline. (figure A)

This part has total ID tolerance of .0003” as well as ID profiling and a milled key that required C-axis contouring. (figure B)

Complex Machining - milling, contouring, off-center drilling

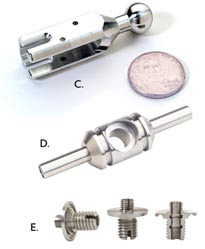

These parts have intricate features that required significant use of milling tools. Please note that all of these parts were built complete on our machines without any second operations.This part required a variety of milling, contouring, and off-center drilling and tapping. (figure C)

Here is a part that demonstrates our ability to cross-drill a hole, mill a counter-bore and then deburr the counter-bore with C-axis contouring in 17-4 Stainless. (figure D)

This part shows the capability to produce ID contours and grooves, a face groove, and a keyway on each end of the part. (figure E)